When it comes to blending powders, granules, or other dry bulk materials, consistency is everything. Uneven mixing can lead to off-spec products, production waste, and costly downtime. That’s where ISC Manufacturing’s Ribbon Mixers deliver results, combining precision engineering, rugged construction, and custom fabrication to meet the needs of virtually any industry.

At ISC, we design and build ribbon mixers that perform in demanding environments, from food and chemical processing to agriculture and construction materials. Each unit is custom-built in-house to meet your material, capacity, and cleanliness requirements.

What Is a Ribbon Mixer?

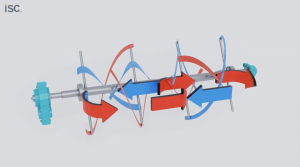

A Ribbon Mixer, also known as a ribbon blender, uses a U-shaped trough and a double-helix agitator, also know as ribbon flights, with inner and outer ribbons. As the agitator rotates, the outer ribbons move material in one direction while the inner ribbons move it in the opposite direction—creating a continuous, gentle folding and blending action.

This counterflow motion ensures uniform mixing in a short time, with minimal energy consumption and minimal product degradation.

How Ribbon Mixers Work

The principle behind the ribbon mixer is simple but highly effective:

-

Outer Ribbons: Move material toward the center of the trough.

-

Inner Ribbons: Move material outward toward the ends.

-

Result: A continuous radial and axial flow pattern that achieves complete blending in minutes.

The result is fast, uniform mixing for dry powders, granules, or light pastes—without overworking or damaging sensitive materials.

Key Advantages of ISC Ribbon Mixers

-

Uniform, Repeatable Blends: Ideal for applications requiring precise consistency, batch after batch.

-

Gentle Mixing Action: Prevents product damage—perfect for friable or heat-sensitive materials.

-

Custom Configurations: ISC engineers each mixer to your process—whether that means variable-speed drives, sanitary construction, or abrasion-resistant liners.

-

Easy Cleanout: Optional hinged covers, discharge gates, and smooth weld finishes simplify maintenance and sanitation.

-

Durability You Can Trust: Heavy-duty shafts, bearings, and troughs built to endure years of continuous service.

Applications Across Industries

ISC Ribbon Mixers are used anywhere bulk materials must be blended quickly and evenly, including:

-

Food & Beverage: Spices, flours, protein powders, and baking mixes.

-

Chemical Processing: Detergents, resins, fertilizers, and pigments.

-

Plastics & Polymers: Pellets, additives, and compounds.

-

Agriculture: Animal feeds, minerals, and seed coatings.

-

Construction Materials: Cement powders, lime, and dry mortar.

Material Options: Built for Your Environment

At ISC, we build ribbon mixers in a range of materials to suit your process and environment:

-

Carbon Steel (CS): Rugged, cost-effective construction for general industrial applications.

-

Stainless Steel (SS 304/316): Corrosion-resistant and sanitary for food, chemical, or pharmaceutical use.

-

AR (Abrasion Resistant) Steel: For handling coarse or abrasive materials like minerals or aggregates.

All welds, finishes, and internal surfaces are tailored to your specifications—from painted carbon steel to fully polished stainless interiors.

Customization Options

Every process is unique—and so is every ISC ribbon mixer. We offer a wide range of customizable options, including:

-

Variable-speed drives and gear reducers

-

Center or end discharges with manual or pneumatic gates

-

Heating or cooling jackets

-

Dust-tight or pressurized covers

-

Replaceable liners or wear bars

-

Custom agitator geometry for difficult-to-mix materials

Whether you need fast batch turnover or gentle homogenization, ISC builds your mixer for maximum performance and reliability.

Ribbon mixers offer the best balance of speed, consistency, and simplicity, making them the go-to choice for most dry bulk blending applications.

Why ISC?

ISC Manufacturing brings decades of experience designing and fabricating bulk material handling equipment—from conveyors to complete mixing systems. Our ribbon mixers are:

-

Engineered to spec – Designed around your exact material, flow, and process requirements.

-

Built to last – Using heavy-duty components, precision welding, and durable finishes.

-

Fully tested before shipment – Ensuring smooth performance and reliability from day one.

Ready to Improve Your Mixing Process?

Whether you’re blending powders, chemicals, or aggregates, ISC Manufacturing delivers the precision, performance, and durability your operation needs.

Contact ISC today to learn more about our ribbon mixers or request a quote.

🌐 www.iscmfg.com

📞 (817) 641-0691