In bulk material handling, even small engineering details can have major operational impacts. One key decision in screw conveyor design is how individual screw sections are joined. Selecting the right coupling method—standard or close-coupled—can influence system reliability, maintenance demands, and flow efficiency. Equally important, but often overlooked, is how those sections are aligned—a concept known as clocking.

At ISC Manufacturing, we engineer screw conveyor systems that move material reliably and predictably. That includes choosing the correct coupling style and ensuring proper flight alignment. Here’s what you need to know.

Standard Coupling: Versatile and Serviceable

Standard couplings use a shaft and bolt pattern to join screw sections with space in between. This space typically allows for the placement of a hanger bearing to support the shaft.

Benefits:

-

Easier to disassemble and maintain

-

Supports hanger bearings for long conveyor runs

-

Compatible with most standard applications and designs

Limitations:

-

Requires internal hanger bearings, which may wear quickly with abrasive or sticky materials

-

Potential for material buildup around bearings and gaps

Standard couplings are widely used in horizontal or gently inclined conveyors, particularly in dry, free-flowing bulk solids applications.

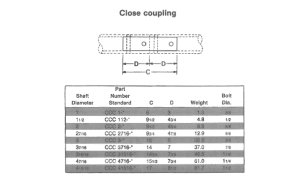

Close-Coupled Screws: Compact and Consistent

Close-coupled designs eliminate the intermediate space between screw sections by minimizing or eliminating the need for a hanger bearing. Sections are joined more tightly and typically supported only at the ends.

Benefits:

-

Removes the need for hanger bearings—ideal for sticky, abrasive, or high-moisture materials

-

Reduces risk of blockages and buildup

-

Allows a more compact overall conveyor footprint

Limitations:

-

Typically not used for long conveyors where shaft deflection could become a concern

-

Can be more complex to fabricate and install due to tighter tolerances

Close-coupled screws are especially useful in applications where internal components like hanger bearings would interfere with material flow or cause excess wear.

Clocking: Seamless Flight Alignment

While standard and close-coupled refer to mechanical joining methods, clocking refers to the angular alignment of flights between screw sections.

In a properly clocked screw, the flights of adjacent sections are matched so material moves smoothly from one to the next. When improperly clocked, flight misalignment can cause turbulent flow, surging, or premature wear at the junction.

Benefits of Clocking:

-

Ensures smooth material handoff between sections

-

Reduces surging, binding, or dead zones

-

Enhances efficiency and extends component life

Key Clarification: Clocking is not a coupling type—it’s an assembly technique that can (and should) be applied to both standard and close-coupled configurations. At ISC, we clock all screw segments unless specified otherwise, to maintain flow continuity.

What About the Flights?

No matter which coupling strategy is used, flight construction matters.

-

Helicoid Flights: Rolled from a continuous strip of steel—ideal for light to moderate-duty applications. Cost-effective with smooth transitions, but limited in customizability.

-

Sectional Flights: Individual segments cut and welded—preferred for heavy-duty, high-wear, or custom-pitch applications. More durable and adaptable to specialty materials.

Clocking and coupling decisions apply equally to both flight styles. ISC manufactures both helicoid and sectional screws, and we engineer each configuration to fit the application.

Engineered for Performance

ISC delivers screw conveyor systems designed for durability, flow performance, and easy maintenance. Every project begins with a detailed understanding of your material and process, so we can design the right flight configuration, coupling method, and alignment strategy from the start.

We fabricate:

-

Standard and close-coupled shafts in carbon or stainless steel

-

Clocked screws for smooth, consistent flow

-

Custom-built conveyors and components for any industry or environment

Let’s Get It Right the First Time

If you’re designing or upgrading a screw conveyor, ISC can help specify the right coupling and flight configuration based on your material, capacity, and layout. Reach out to our engineering team to start the conversation.

ISC Manufacturing

Custom Material Handling Systems

www.ISCmfg.com | 817‑641‑0691